close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-01 Origin: Site

In today’s world, recycling has become a critical part of waste management and environmental sustainability. The increasing amount of plastic waste, especially from bottles, poses significant environmental challenges. However, the solution is within reach: plastic recycling machines. These machines play a vital role in transforming waste materials, particularly plastic bottles, into reusable resources, helping reduce the environmental impact of plastic. This article will provide a comprehensive guide on how to use a plastic bottle recycling machine, with a particular focus on its role in recycling PET bottles.

A plastic recycling machine is a device that processes plastic waste, particularly bottles, into reusable materials such as pellets, flakes, or even raw plastic for manufacturing new products. These machines work by breaking down plastic items into smaller pieces and reprocessing them into a form that can be used in new production cycles. The PET bottle recycling machine is specifically designed to handle PET (Polyethylene Terephthalate) bottles, one of the most commonly used plastics for beverage containers.

PET is known for being lightweight, durable, and versatile. However, once it is discarded, it can take hundreds of years to degrade. By using a plastic bottle recycling machine, we can transform this waste into new products and prevent it from polluting our environment.

PET bottles are widely used in the packaging of beverages, food, and other consumables due to their strength, lightweight nature, and ability to preserve product quality. However, improper disposal of PET bottles contributes significantly to plastic pollution, particularly in oceans and landfills. By using a PET bottle recycling machine, we can significantly reduce this burden and promote a circular economy.

Recycling PET bottles not only helps reduce pollution but also conserves natural resources. The recycled plastic can be used to produce new products like clothing, packaging, and even construction materials. Moreover, recycling saves energy compared to producing plastic from raw materials, making it an environmentally friendly option.

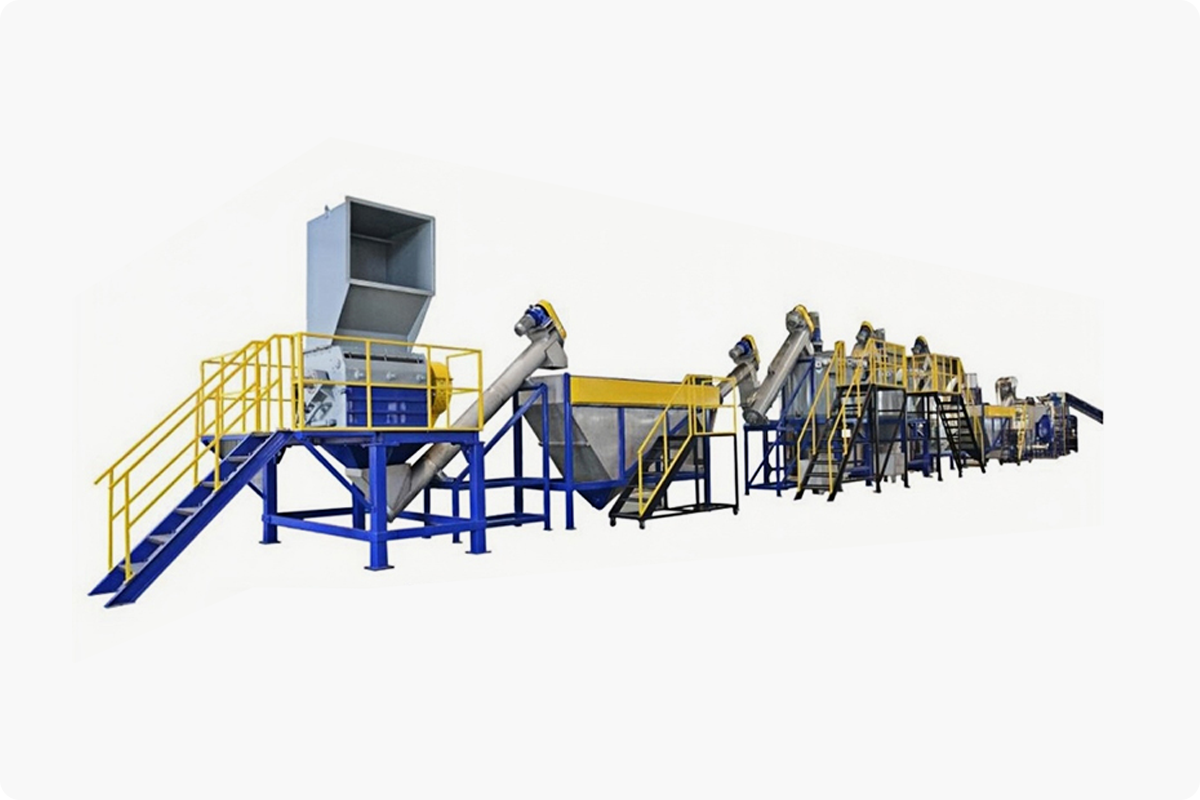

Plastic bottle recycling involves several key machines designed to process different types of plastics and ensure their proper reuse. Below are some of the essential machines used in the recycling of PET bottles:

The PET Bottle Washing Line plays a crucial role in the recycling process by cleaning the collected plastic waste thoroughly. It ensures that contaminants, such as labels, adhesives, and impurities, are removed before the PET bottles are sent to further processing stages. This washing process improves the quality of the recycled material and helps in producing high-quality recycled plastics that are ready for reuse in new products.

The PET Bottle Crusher is used to break down the bottles into smaller pieces. These machines work by using blades or other cutting mechanisms to shred the bottles into manageable sizes, making it easier to handle and process them. The crushing stage reduces the overall volume of the PET bottles, preparing them for the next stage of recycling, whether it's washing, granulating, or pelletizing.

Once the PET bottles have been shredded and cleaned, they are often processed into PET flakes. The PET Flakes Pelletizing Line takes these flakes and transforms them into uniform pellets through a granulating and pelletizing process. The pellets are of consistent size, making them ideal for reuse in manufacturing new plastic products. This stage is essential for creating high-quality recycled plastic that can be utilized in various industries, significantly reducing the need for new plastic production.

Using a plastic recycling machine may seem daunting at first, but the process is quite straightforward. Below are the basic steps involved in using a plastic bottle recycling machine effectively:

The first step in recycling plastic bottles is to collect and sort them. You need to separate PET bottles from other plastic types to ensure that only PET plastic goes into the plastic bottle recycling machine. Sorting is crucial because different plastics require different processing methods.

After the bottles are collected and sorted, they are fed into the plastic crusher or shredder, where they are broken down into smaller pieces. The size of the pieces can vary depending on the machine settings, but generally, smaller pieces are preferred for easier processing.

This includes removing any labels, caps, or contaminants. In industrial settings, this process is done using a plastic washing machine, which uses water and detergents to clean the bottles thoroughly.

After cleaning, the plastic pieces are dried to remove any excess water. This is especially important when recycling PET bottles, as moisture can affect the efficiency of the subsequent steps. Some machines may also preheat the plastic to prepare it for extrusion or pelletizing.

Once the plastic is clean and dry, it is fed into the plastic extruder or pelletizing machine. The extruder melts the plastic and shapes it into a new form, such as pellets or fibers. The pelletizing machine can create small, uniform pellets that are ready to be used in manufacturing new plastic products.

After the recycling process, the final product, whether it is in the form of pellets, fibers, or new plastic products, undergoes quality control to ensure it meets industry standards. This step ensures that the recycled material is free from contaminants and can be used to create new, high-quality products.

Using a plastic recycling machine offers several advantages for businesses, municipalities, and individuals interested in reducing plastic waste:

Recycling plastic bottles significantly reduces the amount of plastic waste that ends up in landfills or the environment. This helps conserve natural resources, reduce energy consumption, and lower greenhouse gas emissions. Recycling plastic also helps prevent pollution in oceans and waterways, where plastic waste can harm marine life.

Recycling PET bottles can save money in the long run. By using recycled plastic, companies can reduce their dependence on virgin plastic materials, which are often more expensive to produce. Additionally, recycling reduces the cost of waste disposal, making it a cost-effective solution for both businesses and households.

Incorporating plastic bottle recycling machines into production lines supports sustainable business practices. Companies that adopt recycling technology contribute to the circular economy by reusing plastic waste to create new products. This can enhance a company’s reputation and appeal to environmentally conscious consumers.

Recycling PET bottles requires less energy than producing plastic from raw materials. The process of melting down and reforming plastic from bottles is far less energy-intensive than producing new plastic from petrochemical feedstocks.

| Machine Type | Main Function | Best For | Advantages |

|---|---|---|---|

| PET Bottle Washing Line | Thorough cleaning of plastic waste, removing contaminants like labels and adhesives | Cleaning PET bottles before further processing | Improves the quality of recycled material, ensuring cleaner plastic for reuse, enhancing the final product quality |

| PET Bottle Crusher | Breaks down PET bottles into smaller pieces | Reducing the volume of plastic waste | Efficient in reducing material volume, making it easier to handle and process in subsequent stages |

| PET Flakes Pelletizing Line | Transforms shredded PET into uniform pellets through granulation | Creating uniform pellets for manufacturing | Produces consistent-sized pellets, ideal for reuse in various industries, reducing reliance on new plastic production |

Using a plastic bottle recycling machine is an efficient and effective way to address the growing issue of plastic waste. These machines, particularly the PET bottle recycling machine, allow businesses and municipalities to process plastic waste into reusable materials that can be used to create new products, saving resources and reducing environmental impact. By understanding how these machines work, the types of machines available, and the steps involved in the recycling process, businesses and individuals can make informed decisions about implementing plastic recycling in their operations.

With advancements in plastic recycling machine technology, recycling PET bottles has never been easier or more efficient. As more companies and individuals embrace these machines, the future of plastic recycling looks brighter, contributing to a more sustainable and eco-friendly world.