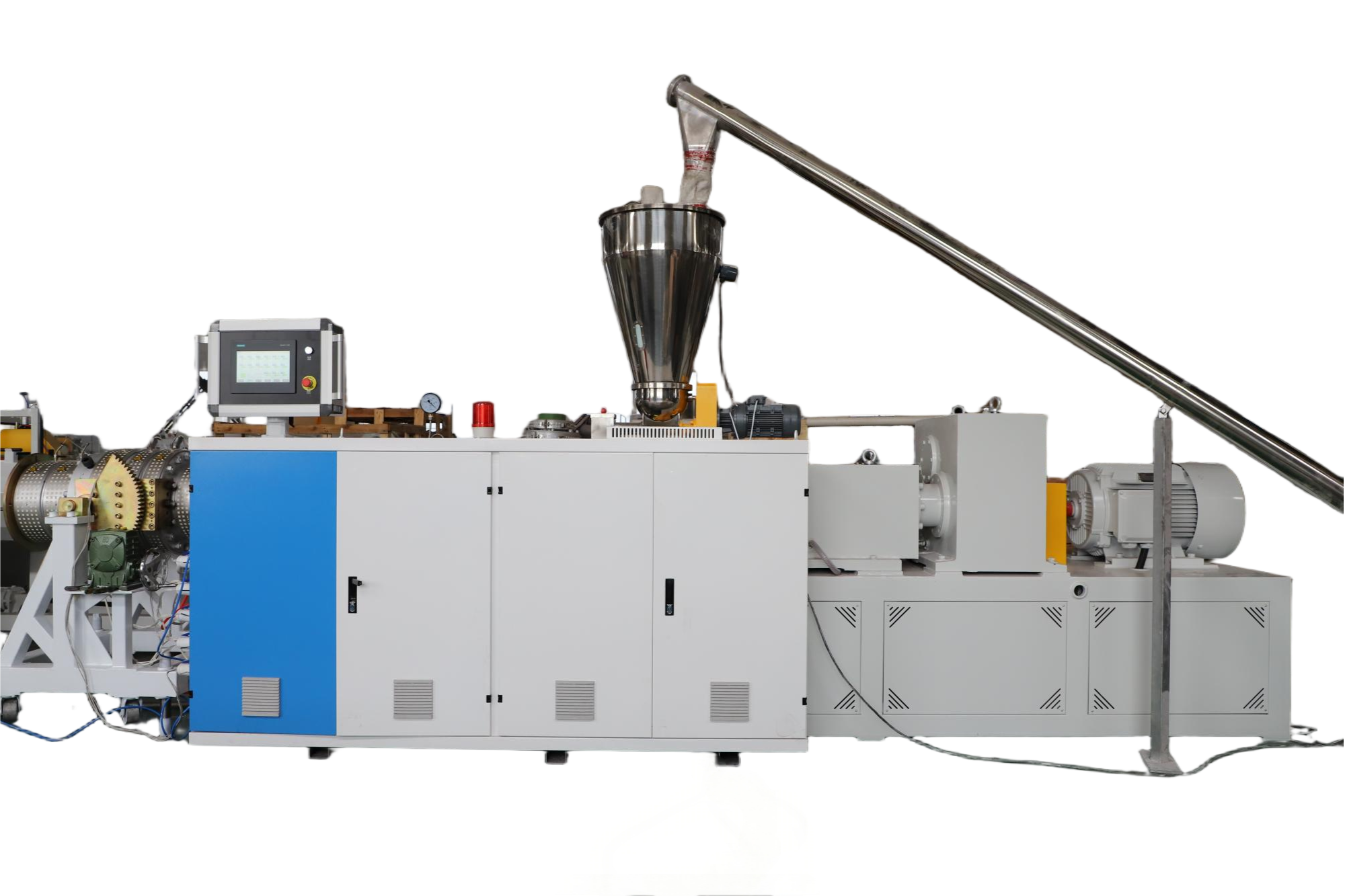

PVC Pipe Machine: High-Efficiency, Durable Solutions for Precision Pipe Production

PVC PIPE MACHINE OVERVIEW

This PVC pipe extrusion machine helps you produce smooth, durable pipes with ease. It features a conical twin-screw extruder with nitrogen-treated bimetallic screws for long-lasting performance. A 40Cr steel mold shapes the pipe, while the vacuum tank cools it precisely. The haul-off unit adjusts to different diameters, and the planetary cutter ensures clean cuts. Powered by Siemens motors and ABB inverters, the system saves energy and runs reliably. As a trusted PVC pipe machine manufacturer, IVIMA offer custom options for agriculture, construction, and electrical applications—helping you grow your production with efficiency and confidence.

| Main extruder | 45/90 | 51/105 | 55/110 | 65/132 | 80/165 | 92/188 | ||||||||||||

| Pipe diameter | 16-63 | 16-40 | 16-63 | 16-32 | 20-110 | 63-200 | 63-200 | 75-250 | 110-315 | 315-630 | 500-800 | |||||||

| Die head | Single cavity | Two cavity | Four cavity | Single cavity | Two cavity | Single cavity | Single cavity | |||||||||||

| Total power | 47 | 60 | 70 | 91 | 85 | 96.5 | 136 | 114 | 145 | 270 | 295 | |||||||

IVIMA PVC PIPE MACHINE FEATURES

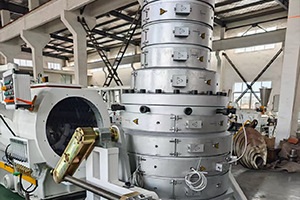

Durable Extruder & Molds

Nitrogen-treated twin screws + 40Cr molds ensure long life & smooth pipes.

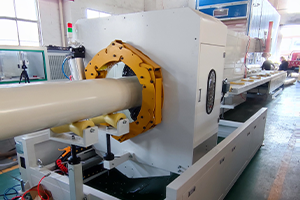

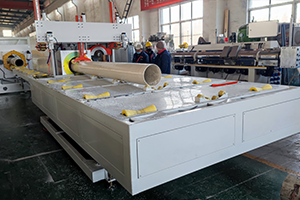

Precision Shaping & Flexibility

Vacuum tank ensures standard dimensions; adapts to various pipe diameters.

Energy-Efficient Drives

Siemens motors + ABB inverters cut costs & boost production stability.

Application

Agriculture & Irrigation

You can use the PVC pipe making machine to produce irrigation pipes for crop fields, greenhouses, and orchards. These pipes carry water to every corner of the farm. You’ll improve water efficiency and reduce waste. They also work well in drip irrigation systems for small farms.

Building & Construction

Your PVC pipe manufacturing machine makes pipes for water supply and drainage in homes, hotels, and office buildings. These pipes are strong, lightweight, and easy to install. You can use them for clean water delivery, rainwater systems, or underground sewage lines. Builders count on PVC pipes for both new projects and renovations.

Electrical & Cable Protection

With a PVC electric pipe making machine, you create protective pipes for outdoor wiring, solar panel cables, or underground fiber optic lines. These pipes shield wires from water, heat, and animals. Telecom and utility companies use them in both city streets and rural areas. They help reduce maintenance costs over time.

Industrial Use

Your PVC pipe extrusion machine supports pipe production for chemical plants, factories, and cooling systems. You can make pipes that move air, liquid, or waste safely. Industrial users need strong, corrosion-resistant pipes that last. These pipes are key in ventilation, fluid transfer, and even dust control systems.

Why Choose IVIMA PVC PIPE MACHINE?

Work with an Experienced Manufacturer

You get a machine from a team that knows PVC pipe systems inside and out. We’ve been building PVC pipe making machines for years and understand what works best.

Get High-Quality, Energy-Saving Parts

Your machine includes strong, reliable parts—like nitrogen-treated bimetallic screws and 40Cr molds. With energy-efficient motors and inverters, you save power while keeping high output.

Choose the Setup That Fits You

We offer customized PVC pipe machine configurations, so you get the exact size, speed, and features you need for your production goals.

Count on Full Support

From setup to training and after-sales service, we’re here to help. You’ll run your machine smoothly and get help whenever you need it.

FAQ

A: The delivery time for our PVC pipe extrusion line is typically 60 working days.

A: We offer a 12-month warranty on our PVC pipe machines to ensure quality and reliability.

A: Yes, we send professional engineers to your factory to assist with installation and provide training for your workers.

A: Yes, we offer customization options to meet specific production requirements for various pipe types.

A: Yes, we provide free replacement for worn-out spare parts during the 12-month warranty period.

Keep in touch with us

If you have any inquiries or needs,don’t hesitate to reach out to our customer service team. Our experienced team is ready to provide you with comprehensive product details and assist you with any questions you may have.