| Availability: | |

|---|---|

| Quantity: | |

Model | Diameter of the screw | Production capacity(kg/h) | Main motor power |

SJSZ45 | 45/90 | 60-120 | 15 |

SJSZ51 | 51/105 | 80-150 | 18.5 |

SJSZ55 | 55/110 | 100-180 | 22/33 |

SJSZ65 | 65/132 | 200-300 | 37 |

SJSZ80 | 80/156 | 300-400 | 55 |

SJSZ92 | 92/188 | 600-800 | 110 |

The PVC ceiling wall grid panel production line is a specialized integrated equipment for manufacturing decorative PVC grid panels—used in interior ceiling and wall decoration. It combines four core processes: extrusion (to form the grid base), cooling (to fix the shape), punching (to create decorative holes), and cutting (to the required length). The line is designed with high automation (≥80% automatic operation) to reduce manual intervention, ensuring consistent product quality (dimensional tolerance ≤±0.5mm) and high production efficiency (up to 8m/min). The produced grid panels feature lightweight, corrosion resistance, and easy installation—making them a mainstream choice in commercial spaces (e.g., shopping malls, hotels) and residential buildings.

Extrusion System: Equipped with a single-screw extruder (barrel diameter 65-90mm) with a specialized grid die (made of H13 steel, precision-machined to Ra ≤0.4μm). The extruder’s heating system (with 4 temperature zones) ensures uniform melting of PVC raw materials (including recycled PVC up to 20% content), achieving a production speed of 3-8m/min. The die’s internal flow channel design prevents material accumulation, ensuring smooth extrusion of grid ribs (thickness 1.5-3mm).

Mold Design: Precision-processed grid mold with 0.02mm dimensional tolerance, producing grids with cell sizes ranging from 10×10mm to 50×50mm (common decorative sizes). The mold’s core components are replaceable, allowing quick changes of grid patterns (e.g., square, rectangular, hexagonal) within 2 hours—supporting diverse design needs for different decoration styles.

Punching Module: Integrated CNC punching machine (with 10-20 punching heads, depending on grid size) featuring high-precision guide rails (positioning accuracy ±0.1mm). It can create customized hole patterns (round, square, hexagonal) with diameters/side lengths from 3mm to 15mm. The punching machine is synchronized with the extrusion line (via encoder feedback), ensuring that holes are aligned with grid cells (no offset) even at maximum production speed.

Cutting System: Flying saw cutting machine (with a high-speed circular saw blade) offering ±1mm length accuracy, cutting panels into lengths from 2m to 6m (as required by customers). The cutting machine features a clamping mechanism to fix the panel during cutting—preventing deformation and ensuring clean cutting edges (no burrs). An optional labeling module can be added to print product information (e.g., size, batch number) on cut panels.

Interior Decoration: Used for ceiling grids and wall panels in shopping malls, hotels, offices, and residential living rooms. The panels have a fire rating of B1 (flame retardant, meeting GB 8624 standards) and low VOC emission (≤1g/L, meeting indoor air quality standards), making them safe for indoor use. Their lightweight (≈0.8kg/m²) reduces installation labor, and the grid structure allows for easy integration of lighting fixtures, air vents, or speakers.

False Ceiling Systems: Serves as the main component of false ceiling systems, supporting ceiling tiles (e.g., mineral wool boards, gypsum boards) with a load-bearing capacity of 5kg/m². The panels are corrosion-resistant (passing 1000-hour salt spray testing), making them suitable for humid environments (e.g., bathrooms, kitchens) where metal grids may rust. They are also easy to clean (via wiping with a damp cloth) and maintain.

Partition Walls: Used to manufacture lightweight partition grids in residential renovations and office spaces. The panels are combined with glass or fabric to create transparent or opaque partitions, reducing wall weight by 40% compared to traditional brick walls. This not only saves construction time (installation speed 20m²/day per worker) but also improves the building’s seismic performance by reducing overall load.

Q: What is the maximum width of the grid panels?

A: Standard width options are 200mm and 300mm (compatible with common ceiling tile sizes); customized molds can support widths up to 1000mm (with modifications to the extrusion die and calendering system). Wider panels require a longer cooling section (≥5 meters) to ensure uniform cooling and prevent warping, and the punching machine needs additional punching heads to cover the wider area.

Q: Are the panels resistant to moisture and mildew?

A: Yes, the panels are made of PVC (a hydrophobic material) with a moisture absorption rate ≤1% (after 24-hour immersion in water)—preventing swelling or deformation in humid environments. They also pass 1000-hour mildew resistance testing (in a high-humidity chamber at 28℃, 95% RH) with no mildew growth, making them suitable for use in bathrooms, basements, and other moisture-prone areas.

Screw Feeder: Used to uniformly and continuously feed raw materials (such as PVC powder) into the extruder.

Twin Screw Extruder: Compared with single screw extruder, twin screw extruder has better mixing performance and wider working range. It is able to efficiently handle multiple material combinations, and the material is plasticized and transported by two meshing screws to form the desired shape.

Vacuum Calibration Table: During the extrusion process, products that have just been formed but have not yet been completely cooled need to be immediately shaped and finished. Vacuum setting tables use the principle of negative pressure to help products cool quickly and maintain accurate dimensions.

Haul-offs: The haul-offs are responsible for smoothly pulling out the preliminary products. By controlling the traction speed, the overall rhythm of the production line can be adjusted.

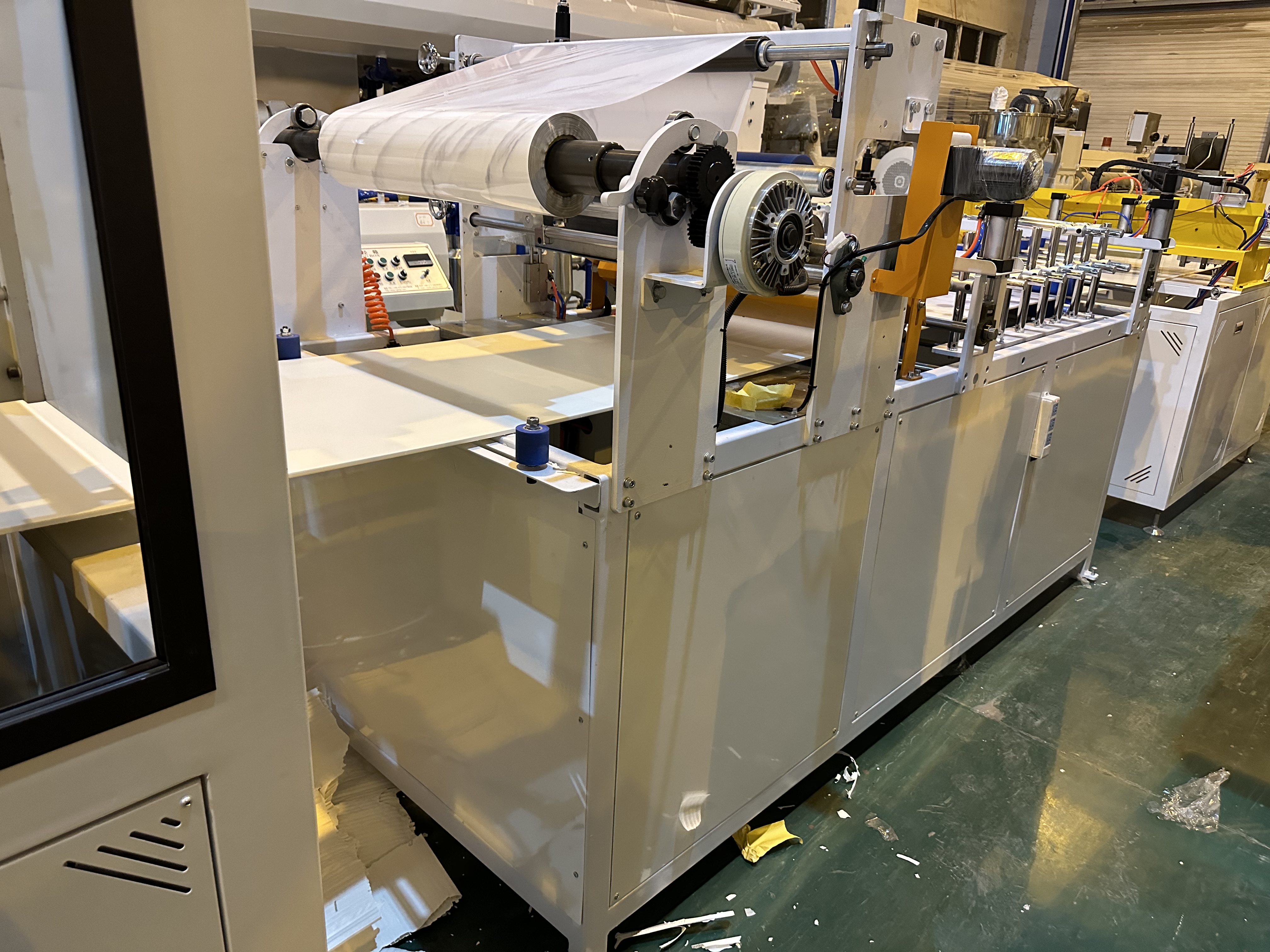

Online Laminating Machine & Hot Stamping Machine:In-line laminating machine: Used to cover the surface of the product with one or more layers of film to increase aesthetics, wear resistance or other special properties.Hot stamping machine: Through heating and pressure, apply metal foil or other decorative materials on the surface of the product to achieve beautifying effect.

Clean Cutter: Responsible for the precise cutting of finished products, ensuring that each product meets the predetermined length standards. It is designed to provide clean cuts and reduce scrap rates.

| Name | Size | Downloads | Update | Thumbnail | Copy Link | Download |

|---|---|---|---|---|---|---|

| PLASTIC RECYCLING 2024-IVIMA.pdf | 10.74MB | 86 | 2024-12-30 |  | Copy Link | Download |

| PLASTIC EXTRUSION 2024- IVIMA.pdf | 12.30MB | 86 | 2024-12-30 |  | Copy Link | Download |