Views: 0 Author: Felix Publish Time: 2026-01-06 Origin: Site

In the competitive world of PE pipe manufacturing, consistency is king. Customers demand pipes that meet exacting standards for wall thickness, pressure ratings, and durability. However, achieving this consistency, especially when working with variable recycled materials, is a constant battle for many manufacturers, who commonly face material waste, high scrap rates, and the risk of product recalls.

What if there was a single technology that could solve these industry pain points at their source?

Enter the gravimetric feeder. This isn't just another piece of equipment; it's the heart of a modern, efficient, and profitable plastic extrusion line. This article will break down why upgrading to a gravimetric feeding system is no longer an option, but a necessity for any serious PE pipe manufacturer.

For years, volumetric feeders were the industry standard. They dose material by volume—a seemingly logical approach. However, this method has a critical flaw: it assumes all raw materials are perfectly uniform.

In reality, the bulk density of PE pellets, and especially recycled PE flakes, can vary significantly. This means that the same volume can have a different weight, leading to:

Inconsistent Throughput: The actual mass of material entering the extruder fluctuates.

Variable Pipe Wall Thickness: These fluctuations directly cause variations in the pipe's meter weight, leading to sections that are either too thin (scrap) or too thick (material waste).

Difficulty Using Recycled Content: The inherent inconsistency of recycled materials makes them nearly impossible to manage effectively with a volumetric feeder.

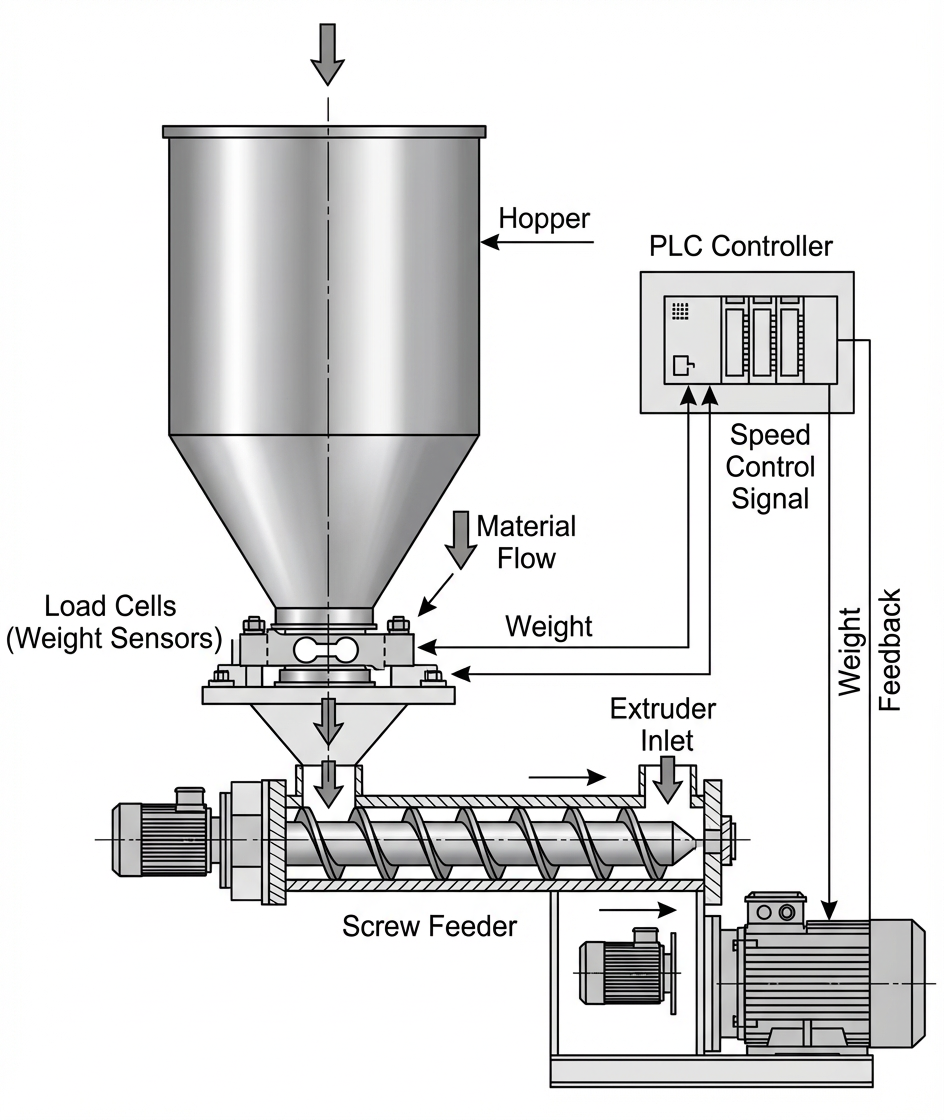

A gravimetric feeder, also known as a Loss-in-Weight Feeder, operates on a simple yet powerful principle: it measures and controls the mass of the material being dosed.

Here’s how it works:

Continuous Weighing: The feeder's hopper is mounted on highly sensitive load cells that continuously weigh the entire system.

Calculating Real-Time Output: As the screw feeds material into the extruder, the controller calculates the exact rate of weight loss per unit of time. This is the true mass flow rate.

Closed-Loop Control: The controller compares this real-time rate to the desired setpoint. If there's any deviation, it instantly adjusts the screw speed to compensate.

This closed-loop system is a game-changer. It automatically corrects for any variations in material bulk density, flowability, or particle size, ensuring the extruder receives a perfectly consistent and precise flow of material.

Upgrading to a gravimetric system delivers tangible benefits that impact everything from product quality to the bottom line.

For PE pipes, quality is defined by dimensional stability. This is achieved through a meter weight control system, which is deeply integrated with the extruder and haul-off unit to maintain a constant weight-per-length of the pipe. The gravimetric feeder is the indispensable core of this system, making it the foundational technology of our advanced PE pipe production lines.

By precisely controlling the meter weight, it's possible to guarantee that the pipe's wall thickness remains uniform, ensuring compliance with strict international standards like ISO 4427 for water supply pipes. This eliminates dimensional deviations and ensures every meter of pipe produced is a high-quality, saleable product.

This is the most immediate and compelling financial benefit. To avoid falling below minimum wall thickness standards, manufacturers using volumetric feeders often produce pipes that are intentionally "overweight." This is pure material giveaway.

A gravimetric system allows the production line to run much closer to the minimum required thickness, eliminating this waste.

Material Savings: Industry data shows savings of 1% to 5% on raw materials.

Rapid ROI: For many companies, the savings on raw materials alone can lead to a return on investment (ROI) in less than one year.

Reduced Additive Costs: Expensive materials like color masterbatch and UV stabilizers are dosed with precision, preventing costly overuse.

As a company specializing in plastic recycling and extrusion, we understand the value and challenges of using recycled PE. A gravimetric feeder is the key to unlocking the full potential of recycled content. Its ability to automatically compensate for the inconsistent density and flow of recycled flakes turns an unpredictable material into a stable, reliable resource, allowing manufacturers to produce high-quality pipes while significantly lowering their raw material costs.

A modern gravimetric feeder is also a powerful data hub. It records a wealth of information, including real-time and average meter weight, actual consumption of each material component, adherence to formulation recipes, and batch/production lot information.

When a quality issue arises, the quality team can use this data for Root Cause Analysis (RCA). Instead of guessing, it's possible to pinpoint the exact moment a deviation occurred. For example, a dip in the meter weight curve can be correlated with a specific batch of raw material or a momentary feeding issue, transforming quality control from reactive to proactive.

To illustrate the difference between the two technologies more intuitively, see the table below:

| Feature | Gravimetric Feeder | Volumetric Feeder |

|---|---|---|

| Principle | Weight-based (Loss-in-Weight), Closed-Loop Control | Volume-based, Open-Loop Control |

| Accuracy | Very High (up to ±0.25%), unaffected by material property changes | Low (approx. ±2%), sensitive to material density and flowability |

| Consistency | Excellent, ensures consistent quality batch after batch | Fair, product quality may fluctuate |

| Cost Control | Saves material (1-5%), reduces waste, high long-term ROI | Low initial investment, but higher material waste and long-term operating costs |

| Automation | High, with self-calibration, data logging, and remote monitoring | Low, requires manual calibration and frequent adjustments |

| Adaptability | Strong, suitable for powders, pellets, flakes, and poor-flowing materials | Poor, sensitive to material characteristics |

In today's market, a gravimetric feeder is far more than a simple upgrade. It is a strategic investment in quality, efficiency, and profitability.

By providing unparalleled control over the material feed, a gravimetric system enables manufacturers to:

Guarantee product quality that meets the toughest standards.

Save 1-5% on raw material costs, delivering a rapid ROI.

Confidently use cost-effective recycled materials, boosting sustainability and profitability.

Create a data-driven quality control process that builds customer trust.

Stop wasting money on uncertainty. Invest in a future of precision and efficiency.

Our PE pipe production lines are already integrated with the most advanced meter weight control technology, ready to revolutionize your business.

Contact us today to have our engineers demonstrate how this technology will directly boost your profitability and to receive a customized ROI analysis report!