In the growing market of plastic pipes, PPR pipes (Polypropylene Random Copolymer) are an essential part of modern plumbing and heating systems. These pipes are renowned for their durability, ease of installation, and resistance to corrosion. With the increasing demand for PPR pipes, selecting the right PPR pipe machine for your production line has become a critical decision for manufacturers. This article will guide you through the essential features, benefits, and considerations for choosing the right PPR pipe machine for your pipe production line.

What is a PPR Pipe Machine?

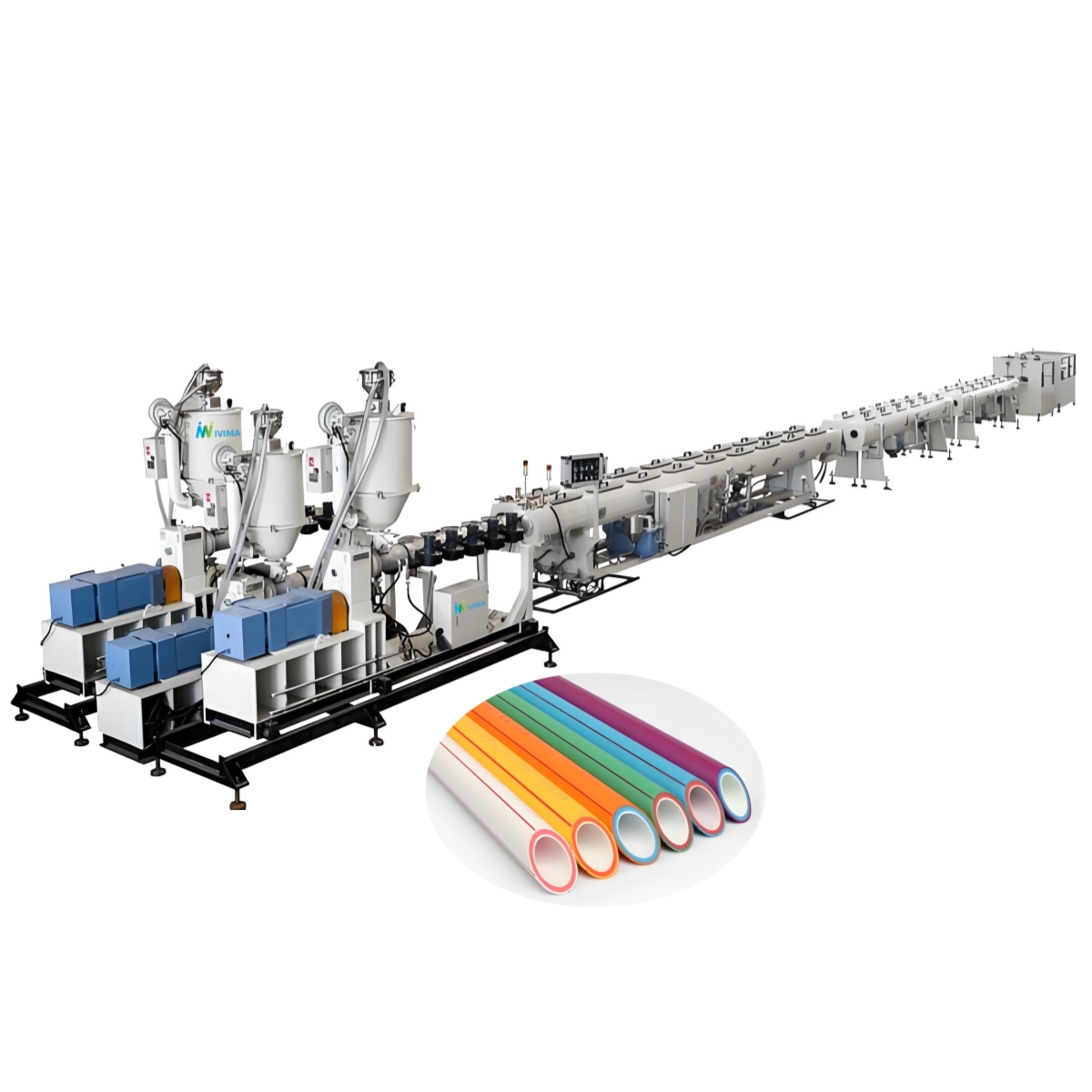

A PPR pipe machine is a specialized extrusion system used to manufacture PPR pipes. It includes several components such as high-efficiency extruders, composite molds, vacuum tanks, water cooling tanks, haul-off machines, cutters, and stackers. The machine works by processing raw materials and converting them into high-quality, durable pipes suitable for use in plumbing, heating, and industrial applications.

Key Components of a PPR Pipe Production Line

Understanding the components of a PPR pipe machine is essential when choosing the right equipment for your production needs. A typical PPR pipe production line includes:

Extruders: These machines melt and extrude the raw materials into a pipe shape. For PPR pipes, two single-screw extruders are typically used. One extruder is responsible for producing the inner and outer layers, while the other extrudes the middle layer.

Co-extrusion Die Head: This specialized die head allows for the production of multi-layer pipes, typically three layers, including an inner and outer layer of PPR, and a middle layer that enhances the pipe's strength.

Vacuum Tank: This essential component shapes and cools the pipe, ensuring that it reaches the desired diameter and shape.

Cooling Tank: After the vacuum tank, the cooling tank helps the pipe maintain its structure and cools it down to a solid state.

Haul-off Machine: The haul-off machine is responsible for pulling the pipe through the production line while ensuring that it maintains its form. It also stabilizes the extrusion speed to maintain consistent quality.

Cutter: The cutter cuts the pipe into the desired lengths as it exits the line, providing precise and accurate cuts.

Characteristics of PPR Pipe Extrusion Machine

The choice of PPR pipe machine can significantly impact the efficiency, quality, and overall success of your production line. Below are some essential characteristics to consider:

1. Extruder Design

A PPR pipe machine requires a high-efficiency extruder. To produce high-quality multi-layer pipes, the machine should be equipped with two single-screw extruders. One extruder is used for the inner and outer layers, while the other is dedicated to the middle layer. The extruders should be designed to handle different types of PPR materials and additives effectively, ensuring smooth and consistent extrusion.

2. Co-Extrusion Die Head

The die head plays a critical role in the formation of multi-layer pipes. For PPR pipe production, a co-extrusion die head with a special composite design for three-layer extrusion is required. This die head ensures that the three layers of the pipe (inner, middle, and outer) are extruded simultaneously and bonded together effectively.

3. Vacuum Tank

The vacuum tank is responsible for shaping and cooling the three-layer pipe to achieve the correct size and shape. A well-designed vacuum tank typically features an advanced multi-chamber anti-deformation structure, which ensures that the pipe maintains its shape even during the cooling process. The tank’s double-loop pipeline design allows for continuous cleaning and temperature control, ensuring consistent production quality.

4. Cooling Tank

The cooling tank is crucial for solidifying the extruded pipe and ensuring that it retains its shape. Cooling tanks should be designed for ease of use and maintenance, with a spray effect that ensures even cooling across the entire length of the pipe. The cooling tank structure is usually similar to that of foreign advanced machines, with a focus on minimizing pipe deformation.

5. Haul-off Machine

The haul-off machine is responsible for pulling the pipe through the production line. It should be equipped with a traction device, such as a V-type rubber block caterpillar, and controlled by an imported inverter for stable operation. The machine should be compact, easy to maintain, and capable of handling varying pipe sizes without compromising production speed.

6. Cutter

The cutter is essential for producing precise lengths of pipe. It should be designed to cut the pipe accurately and efficiently. Many modern cutters feature PLC-controlled cutting processes, allowing for arbitrary length cutting with high precision. The cutter’s design should include a clear glass window for easy observation and maintenance.

Process Flow of PPR Pipe Production

![PPR Pipe Production Line PPR Pipe Production Line]()

Understanding the flow of the PPR pipe production process is essential when selecting a machine that will best meet your needs. The general process involves several stages:

Raw Material Mixing: The first step in the production process is mixing the raw materials and master batches.

Vacuum Feeding: The mixed materials are fed into the machine via a vacuum feeding system to ensure uniform distribution.

Single Screw Extruder: The material is then processed through a single-screw extruder, which melts and forms the pipe shape.

Color Line Extruder: This step adds any desired color to the pipe.

Co-extrusion Mould: The pipe is formed into its final shape through a co-extrusion mould.

Calibration: The pipe is calibrated to the desired size and shape using a calibrator.

Vacuum Calibration Tank: The pipe passes through a vacuum calibration tank where it is cooled and solidified.

Cooling Water Tank: The pipe is further cooled in the cooling water tank to ensure stability.

Haul-off and Cutting: The pipe is hauled off and cut into the required length.

Stacking: Finally, the pipes are wound into stacked for easy transportation.

Key Considerations When Choosing a PPR Pipe Machine

When selecting a PPR pipe machine for your production line, it’s essential to consider several factors to ensure that you choose the best equipment for your needs:

1. Production Capacity

The production capacity of the machine should match your requirements. High-efficiency machines are ideal for large-scale production, while smaller machines may be more suitable for smaller operations.

2. Quality and Durability

Quality should always be a top priority. Look for machines that are built with durable materials and designed for long-lasting performance. A well-built machine will require fewer repairs and have a longer operational life.

3. Customization Options

Different production lines may require custom solutions. Machines that offer customizable features, such as adjustable various pipe sizes, will provide more flexibility and ensure that your production line can adapt to different requirements.

4. Ease of Maintenance

A PPR pipe machine that is easy to maintain will reduce downtime and improve overall productivity. Look for machines that feature easy access for cleaning, as well as a design that minimizes the risk of breakdowns.

5. Cost-Effectiveness

While it’s essential to invest in high-quality equipment, it’s also important to consider the cost. Balance the initial investment with the machine’s long-term operational costs, including energy consumption, maintenance, and repair.

Conclusion

Choosing the right PPR pipe machine for your pipe production line requires careful consideration of various factors, including machine components, production capacity, and long-term durability. By understanding the key features and process flow of a PPR pipe machine, you can make an informed decision that aligns with your business goals. Invest in high-quality, efficient, and customizable machines to ensure the success of your PPR pipe production line.

FAQs

1. What are the applications of PPR Pipe Machines?

PPR Pipe Machines are used to produce pipes for hot water systems, plumbing, heating, and irrigation.

2. What types of PPR pipes can a PPR Pipe Machine produce?

PPR Pipe Machines can produce single-layer and multi-layer pipes, including three-layer pipes.

3. What are single-layer PPR pipes used for?

Single-layer PPR pipes are used in residential and commercial plumbing for hot and cold water distribution. They are durable, corrosion-resistant, and cost-effective for low-pressure applications.

4. What are multi-layer PPR pipes used for?

Multi-layer PPR pipes, especially three-layer pipes, are used in high-pressure systems, underfloor heating, and other demanding applications due to their enhanced strength and insulation.