IV

IVIMA

| Availability: | |

|---|---|

| Quantity: | |

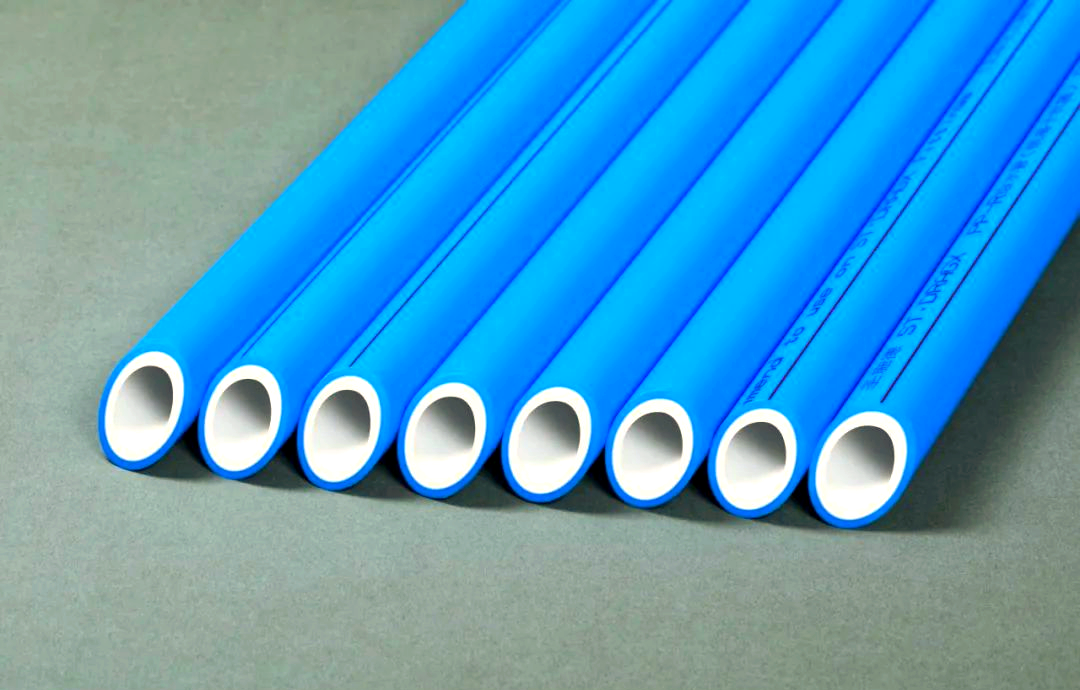

PPR pipe production line

Advantages:

Motor: Siemens/WEG

Inverter:ABB

Temperature controller: Omron/RKC

Other electric element: internation famous brands

Specifications:

Model | Pipe range(mm) | Total length(m) | Hauling speed(m/min) |

PPR63 | φ16-63 | 35 | 1.2-12 |

PPR110 | φ20-110 | 38 | 1.0-10 |

PPR160 | φ50-160 | 40 | 0.8-8 |

We can produce either one layer or multilayer PPR pipe production line, common speed or high speed.

Process line:

Raw material +master batches → mixing→vacuum feeding → material dryness → single screw extruder → single screw extruder → single screw extruder → color Line extruder → co-extrusion mould → calibrator → spray vacuum calibration tank → spray coolingwater tank → word printer → haul-off → no-dust cutter → pipe rack→finished product.

Final PPR pipe:

Extruder: It need to equip two single screw extruders, one for extruding inner and outer pipes layer, another for middle layer.

Co-extrusion die head: Special composite design for three-layer pipe extrusion.

Vacuum tank: It is used to shape and cool three layers pipe, so as to reach standard pipe size. Its shape is advanced foreign multilateral anti-deformation structure.

The cover is made of high quality casting aluminum alloy.

Its inside is double-chamber structure. The pipeline adopts the design of double loop pipeline, realizing non-stop pipeline clean and function of temperature control.

Cooling tank: Supporter structure are similar with foreign advanced machine and convenient to observe spray effect.

Haul off machine: Its structure with sliding tempering glass door is beautiful and practical. Traction device with V type rubber block caterpillar and controlled by imported inverter can steadily haul pipe. It also features compact structure and free-maintenance.

Cutter: Its structure is beautiful and practical with glass window design. Cutting process is controlled by PLC, can realize accurately arbitrary length cutting.

Winder: Use torque motor, winding speed is adjusted automatically based on tension. Automatic winding displacement uniformity. Apply double station, ensure continuous production. Pneumatic coiling spoke, easy to open and close. Winding inner diameter is adjustable, to ensure no deformation of pipe during winding.

What after-sales service does your factory provide?

A. 12 months since machine installation and running. During this guarantee period, IVIMA will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, IVIMA will provide the buyer spare parts at cost price.

B. IVIMA will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

| Name | Size | Downloads | Update | Thumbnail | Copy Link | Download |

|---|---|---|---|---|---|---|

| PLASTIC RECYCLING 2024-IVIMA.pdf | 10.74MB | 66 | 2024-12-30 |  | Copy Link | Download |

| PLASTIC EXTRUSION 2024- IVIMA.pdf | 12.30MB | 71 | 2024-12-30 |  | Copy Link | Download |